Coalescers and Oil Water Separators

A Coalescer is a technological device performing coalescence. They are primarily used to separate emulsions into their components via various processes operating in reverse to an emulsifier.

A coalescer can be either a mechanical or electrostatic one. Mechanical coalescers use filters or baffles to make droplets coalesce while electrostatic coalescers use DC or AC electric fields (or combinations).

In the area of compressed air purification, coalescing filters are used to separate liquid water and oil from compressed air using a coalescing effect. These filters additionally remove particles. The most commonly used media in this case is Borosilicate micro-fiber.

In the Oil and Gas, Petrochemical and Oil Refining industries, Liquid-Gas coalescers are widely used to remove water and hydrocarbon liquids to <0.011 ppmw (plus particulate matter to <0.3 um in size) from natural gas to ensure natural gas quality and protect downstream equipment such as compressors, gas turbines, amine or glycol absorbers, molecular sieves, PSA's, metering stations, mercury guard beds, gas fired heaters or furnaces, heat exchangers or gas-gas purification membranes.

In the Natural Gas industry, gas/liquid coalescers are used for recovery of lube oil downstream of a compressor. All liquids will be removed but lube oil recovery is the primary reason for installing a coalescer on the outlet of a compressor. Liquids from upstream of the compressor, which may include aerosol particles, entrained liquids or large volumes of liquids called "slugs" and which may be water and/or a combination of hydrocarbon liquids should be removed by a filter/coalescing vessel located upstream of the compressor. Efficiencies of gas/liquid coalescers are typically 0.3 Micron liquid particles, with efficiencies to 99.98%.

Liquid-liquid coalescers can also be used to separate hydrocarbons from water such as oil removal from produced water (Oil and Gas industry). They have been also used in pyrolysis gasoline (benzene) removal from quench water in ethylene plants, although in this application, the constant changing of cartridges can lead to operator exposure to BTX (benzene, toluene and xylene), as well as disposal issues and high operating costs from frequent replacement.

Electrostatic coalescers use electrical fields to induce droplet coalescence in water-in-crude-oil emulsions to increasing the droplet size. The squared dependence of droplet diameter in stokes law, increase the settling speed and destabilizes the emulsion. The effects on the water droplet arise from the very different dielectric properties of the conductive water droplets dispersed in the insulating oil. Water droplets have a permittivity that is much higher than the surrounding oil. Furthermore, water with dissolved salt is also a very good conductor. When a uncharged droplet is subjected to a AC electric field the field will polarize the droplet creating a electric field around the droplet to counteract the external field. As the water droplet is very conductive the induced charges will reside on the surface. The droplet has no net charge but one positive and one negative side. Inside the droplet the electric field is zero. When two droplets with induced dipoles gets close to each other, they will experience a force pulling the droplets closer until they coalesce.

In oil production, co-produced water is mixed with the oil in choke valves and process equipment producing water-in-oil emulsions. The amount of water increases during the production life of the reservoir. The emulsions are destabilized using gravitational separators, and the settling rates are increased by applying heat, demulsifiers, and AC electric fields. The AC electric field gives rise to attractive forces between water droplets, and increases the probability of coalescence at contact. According to Stokes law, the settling rate increases proportionally with the square of the drop diameter. By promoting coalescence of small water droplets, the settling rate can be greatly increased. The water content is normally reduced to <0.5 vol% if this is the final treatment stage before the crude oil is exported.

Typical electrocoalescers are large settling tanks containing electrodes and operates under laminar-flow conditions with bare electrodes that may be vulnerable to short circuiting. An alternative to this type of coalescer is a flow through pre-coalescer that is installed upstream a separator tank. In the Compact Electrostatic Coalescer. Droplet coalescence is achieved by applying AC electric fields (50–60 Hz) to water-in-oil emulsions under turbulent-flow conditions. The turbulence increases the collision frequency between the water drops. The electrodes are insulated to prevent short circuiting, and permits water contents of up to 40% as well as water slugs. The equipment is a separate flow-through electrostatic treatment section installed upstream of a gravity separator to improve the performance. By keeping the treatment and settling sections separate, a compact electrostatic coalescer can be obtained that can also be retrofitted.

Liquid-liquid coalecers are also widely used in oil refining industry to remove the last traces of contaminants like amine or caustic from intermediate products in oil refineries, and also for the last stage dewatering of final products like kerosene (jet fuel), LPG, gasoline and diesel to <15 ppmw free water in the hydrocarbon phase. These coalescers are often electrostatic type, in which a DC electrical field encourages the water droplets to coalesce thus settling by gravity

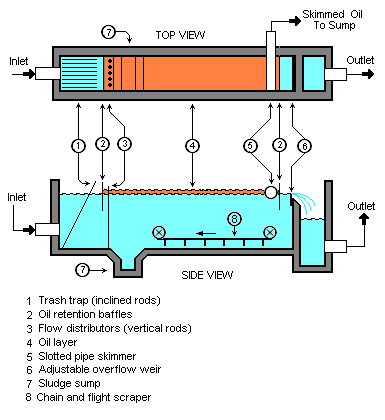

An API oil-water separator is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of oil refineries, petrochemical plants, chemical plants, natural gas processing plants and other industrial sources. The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute (API).

A typical gravimetric API separator

The API separator is a gravity separation device designed by using Stokes Law to define the rise velocity of oil droplets based on their density and size. The design of the separator is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom.[2]

Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment consisting usually of a dissolved air flotation (DAF) unit for further removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

A typical parallel plate separator

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Any sediment slides down the topside of each parallel plate. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

A typical parallel plate separator

The API separator was developed by the API and the Rex Chain Belt Company (now Siemens Water). The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in Philadelphia. Since that time, virtually all of the refineries worldwide have installed API separators in their wastewater treatment plants. The majority of those refineries installed the API separators using the original design based on the specific gravity difference between oil and water. However, many refineries now use plastic parallel plate packing to enhance the gravity separation.

There are other applications requiring oil-water separation. For example:

Oily water separators (OWS) for separating oil from the bilge water accumulated in ships as required by the international MARPOL Convention.

Oil and water separators are commonly used in electrical substations. The transformers found in substations use a large amount of oil for cooling purposes. Moats are constructed surrounding unenclosed substations to catch any leaked oil, but these will also catch rainwater. Oil and water separators therefore provide a quicker and easier cleanup of an oil leak.

Major suppliers of oil-water supplier equipment:

Kingspan Environmental

Conder Environmental

Hydroambiente

Developped by Rami E. Kremesti M.Sc.