TRANSFORMING BASE SUBSTANCES INTO GOLD

Cooling Water Treatment Basic Principles

by Rami E. Kremesti M.Sc., CSci, CEnv, CWEM

Kremesti Environmental Consulting Ltd.

Introduction

A cooling water system is used for cooling various processes. There are evaporative open cooling systems in which hot water evaporation cools down the water and dry air heat exchanger types of cooling systems. Adiabatic cooling systems are hybrid.

In Closed cooling systems, water has no direct contact with air. They are used for example on power stations to cool large rotating equipment and part of chiller systems in large HVAC systems used in buildings.

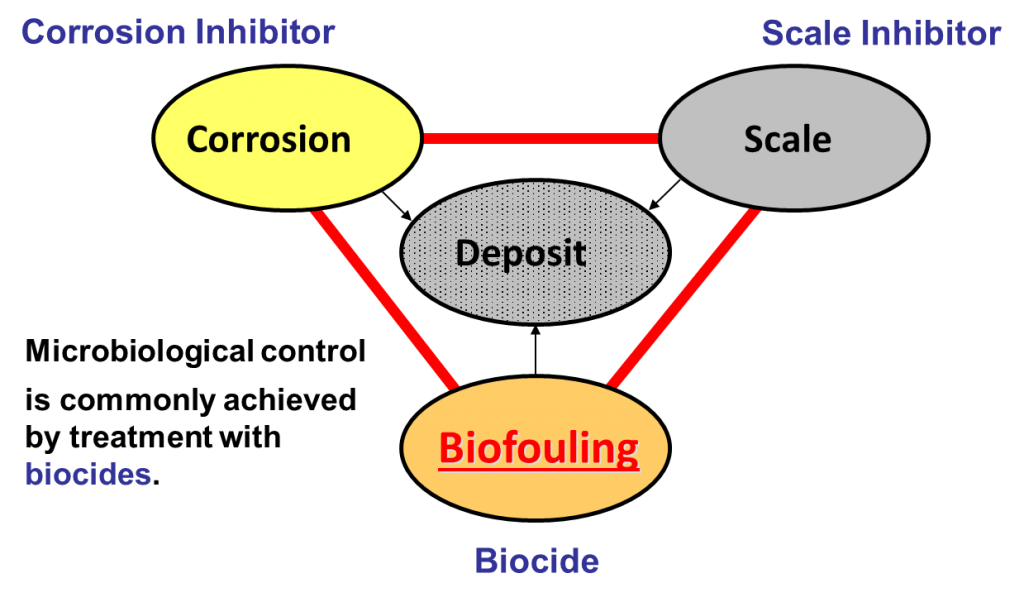

Cooling systems need treatment and monitoring to prevent problems such as corrosion, scale, fouling, freezing and bio-fouling. Protecting human health is also important especially for open cooling systems that can act as incubators for harmful bacteria such as Legionella. There is an increase in popularity of Chemical-Free water treatment as well as using Green Chemistry.

What does a cooling water treatment system typically control/measure/treat?

A cooling water treatment system, whether open or closed, consists of technologies necessary to regulate the level/extent of:

1. alkalinity and hardness: control the potential of calcium carbonate scale. Scale on the heat exchanger of a cooling tower can significantly reduce the efficiency of heat exchange.

2. chlorides: can be corrosive to metals; different levels will be tolerated based on materials of the cooling tower and the auxiliary equipment

3. hardness: contributes to scale in the cooling tower and on heat exchangers

4. iron: when combined with phosphate, iron can foul equipment. Also levels of iron in the water indicate if there is low or high corrosion rates.

5. organic matter: promotes microorganism growth, which can lead to fouling, corrosion, and other system issues such as foaming. It can also lead to fouling of other equipment treating the blow-down water such as Reverse Osmosis skids.

6. silica: is known for causing hard scale deposits especially when combined with magnesium.

7. sulphates: like chlorides, can be extremely corrosive to metals and can form scales such as BaSO4 and CaSO4. In an acidic environment, or in cased of SRB’s, H2S can form which is also corrosive.

8. total dissolved solids (TDS): contribute to scaling, foaming, and/or corrosion

9. totals suspended solids (TSS): undissolved contaminants can cause scaling, feed biofilm, and/or corrosion and can harbour bacteria

10. Bacteria and Algae: bacteria and algae result in biofouling on the cooling system surfaces thus resulting in heat exchange efficiency loss and can lead to the necessity of expensive cooling system component replacements such as pack replacements. In addition, certain bacteria, such as Legionella, if they proliferate in a cooling water system represent a health hazard which is required to be controlled by Law. There is also a risk that under-deposit biofilm, and a phenomenon called Microbial-Induced Corrosion can occur.

11. Ammonia: certain cooling waters can contain Ammonia which together with Dissolved Oxygen can be very corrosive to yellow metals such as Copper and Brass.

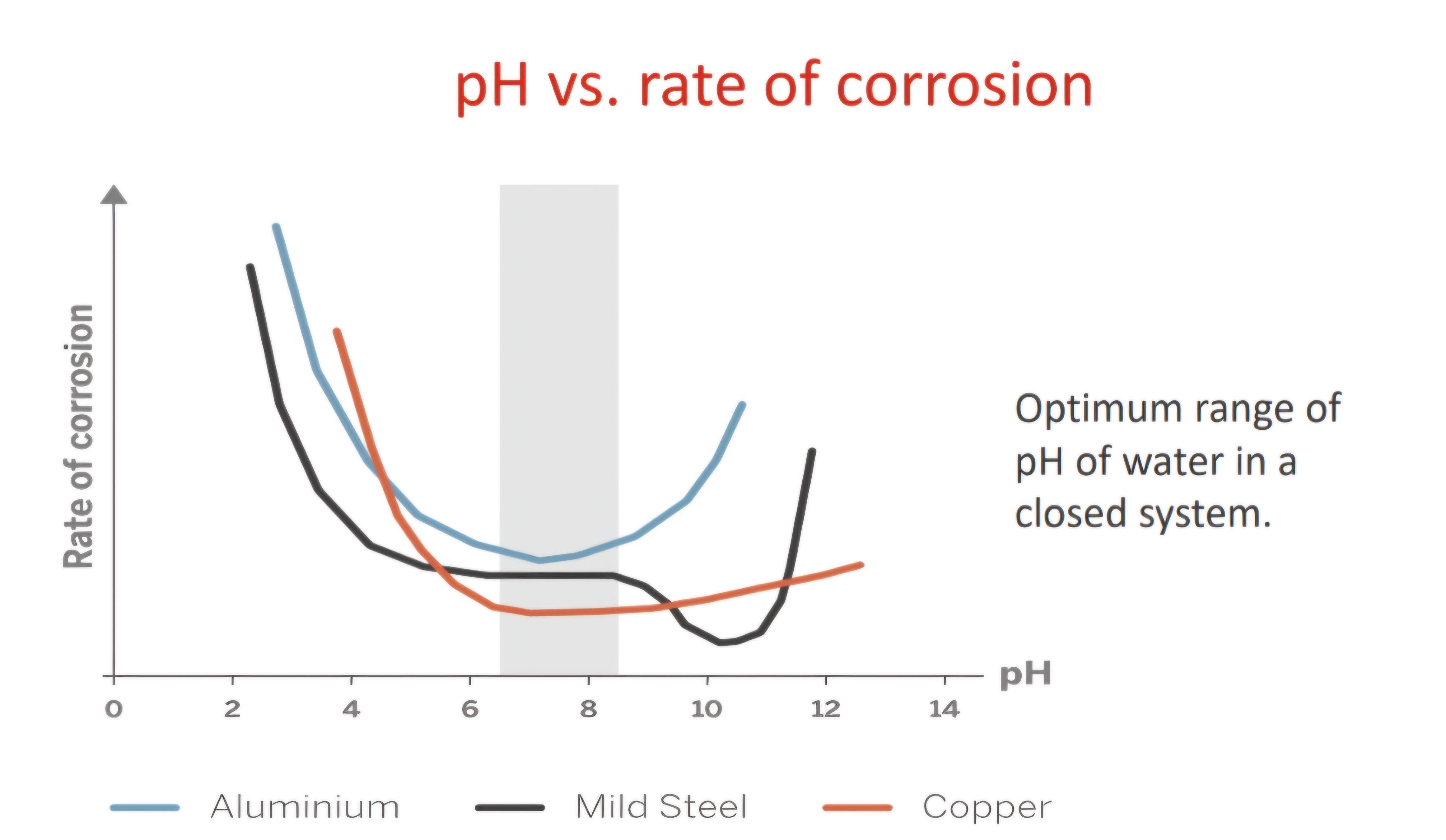

12. pH: this indicator measures the acidity in the water and this parameter is very important in a cooling tower as it affects the corrosive effects of the water. Some metallurgies need more alkaline water, some metallurgies are stable at lower pH levels.

13. Nitrates/Nitrites: some cooling systems are dosed with nitrites that are used as corrosion inhibitors.

More Parameters to Look Out For

13. LSI: The Langlier Saturation Index is an indicator of whether a cooling water is balanced i.e. neither scaling nor corrosive.

14. Dissolved Oxygen: Closed Cooling Water Systems are less prone to corrosion if the DO is kept next to zero.

A good illustration of the main cooling water system problems is below:

Types of Corrosion

There are several types of corrosion that can affect a cooling system:

- General corrosion,

- pitting corrosion,

- under-deposit corrosion,

- Microbial Induced Corrosion and

- stress corrosion cracking

ALWAYS keep in mind the pH vs corrosion rate of various metals. Mixed metal systems are more tricky. Also always check the material compatibility of materials for example ammonia and DO are a very corrosive combination for copper systems.

Technologies used in Cooling Water Treatment:

Makeup water, or the water replacing bleed, evaporated and carryover from the cooling tower, is first drawn from its source, which could be raw water, city water, city-treated effluent, recycled in-plant wastewater , well water, or any other surface water source.

Depending on the quality of this water, you may or may not need treatment. If a water treatment system is needed at this part of the cooling tower water process, it is usually technology that removes hardness and silica, stabilises and adjusts the pH and/or disinfects the system to control levels of bacteria and algae.

At this point of the process, the proper treatment optimises the tower evaporation cycles and minimises the water bleed rate to drain beyond what might be done with chemicals alone.

1. Clarification and Softening of Make Up Water for Cooling Towers

Some cooling towers use make up water from a hard surface source such as a river or lake. In this case it is necessary to treat the make up flow of water through a clarifier to remove suspended solids as well as hardness in the water. Clarifiers normally use a coagulant such as Ferric Chloride and flocculants which are polymers that help suspended coagulated particles to coalesce and settle in the clarifier.

2. Filtration and Ultra Filtration (UF) for Pre-treatment of Cooling Water

The next step is generally running the cooling tower water through some type of filtration to remove any suspended particles such as sediment, turbidity, and certain types of organic matter. It is often useful to do this early on in the process, as the removal of suspended solids upstream can help protect membranes and ion exchange resins from fouling later on in the pre-treatment process. Depending on the type of filtration used, suspended particles can be removed down to under one micron.

3. Ion exchange/water softening for Cooling Water

If there’s high hardness in your source/makeup water which is sometimes municipal such as City of London water, there may be need for treatment to remove the hardness. Instead of lime/soda ash softening, a softening resin can be used: a strong acid cation exchange process, whereby resin is charged with a sodium ion, and as the hardness comes through, it has a higher affinity for calcium, magnesium, and iron so it will grab that ion and release the sodium ion into the water. These contaminants, if present, will otherwise cause scale deposits and rust. Note that Nano-filtration can also soften water.

4. Chemical Dosing in Cooling Waters

Certain chemicals sometimes need to be added to the cooling water such as:

a. corrosion inhibitors to protect metal components – if needed. Sometimes the water can be balanced.

b. algaecides and biocides (e.g., bromine) to reduce the growth of algae, microbes and biofilms. Ultrasonic Sound Generators have also been used to reduce the bacterial burden in cooling waters.

Technologies such as SONOXIDE or LG Sonic are in use which are chemical free. Always remember, if you can lower the N and P in the water, you can create a more Biostable water.

Ozone is considered an environmentally friendly oxidising biocide. DBNPA and Glutaraldehyde are two examples of non-oxidising biocides.

c. scale inhibitors (e.g., phosphoric acid/phosphonates) to prevent contaminants from forming scale deposits

d. dispersants to prevent deposition of debris

Thorough treatment prior to this stage can help reduce the amount of chemicals needed to treat water at this point in the process, which is ideal considering many chemical treatments can be expensive.

e. defoamers or anti-foam chemicals

Chemical Free Water Treatment for cooling systems is gaining more and more traction. For example, when I used to work for ALSTOM, the closed cooling water systems were filled with demin water and dosed with tiny bit of NaOH to increase the pH. This minimalist approach can prevent corrosion, scale and biofouling.

VDI 2035 is the relevant German guideline that advocates for chemical-free water treatment in closed heating and cooling systems by focusing on controlling water quality parameters, rather than relying solely on chemical inhibitors. BSRIA BG 89 is a similar standard that is under development.

5. Side-stream filtration for Cooling Towers/Systems

If the cooling tower water is going to be recirculated throughout the system, a side-stream filtration unit will be helpful in removing any problematic suspended contaminants that can enter through forced draft contamination, process leaks, etc. A good rule of thumb is that, if you cooling tower water treatment system requires side-stream filtration, about 10% of the circulating water will be filtered through. It typically consists of a good quality multimedia filtration unit or a cyclone filter. It is also possible to subject side-streams to Sonication as a chemical free way to reduce bacterial numbers.

6. Blow-down treatment for Cooling Towers

The last part of treatment required for a cooling tower is the blow-down or bleed from the tower.

Depending on how much water the cooling plant needs to circulate for proper cooling capacity, plants will choose to recycle and recover the bleed water through some type of post treatment in the form of reverse osmosis, EDI or ion exchange, especially in places where water might be scarce. This allows liquid and solid waste to be concentrated and removed while treated water can be returned to the tower and reused.

Green Chemistry and Low Embedded Carbon Formulations

Green Chemistry is the use of chemicals for water treatment and other processes that are environmentally friendly. For example, Tanafloc offers organic coagulants that are biodegradable and non-toxic in sludge. Veolia has the Hydrex range.

Electro-Coagulation eliminates the need for transporting large volumes of water treatment coagulants by generating ferric and aluminium coagulants in situ using solid sacrificial anodes and electricity.

A company called Chemion offers low carbon formulations.

D-Limonene, a natural citrus derivative, acts as a powerful, biodegradable solvent and degreaser in water treatment and cleaning, used to break down oils, greases, and resins, often combined with surfactants to create water-dilutable cleaners for industrial equipment, machinery, and wastewater to float contaminants to the surface.

Electro-Chlorination is a method to generate hypochlorous acid on site using DC current and NaCl brine solutions. I have personally worked on a power station in Algeria called Terga that uses such a system from DeNora.

Cooling Tower Calculations (Mass and Heat Balance)

Mass and heat balance calculations for cooling towers involve determining the heat rejected by the water, the cooling air flow rate, and the amount of water evaporated/carried over using equations based on water flow, temperature changes, and air properties. Blow down and make up water flow rates plus evaporation determine the CoC = Cycles of Concentration.

Q = m * Cp * (Tin - Tout)where

Q= Heat rejected (e.g., kW or BTU/hr)and

m= Mass flow rate of water (e.g., kg/s or lb/hr)Cp= Specific heat capacity of water (approximately 4.18 kJ/kg·°C or 1 BTU/lb·°F)Tin= Inlet water temperature (e.g., °C or °F)Tout= Outlet water temperature (e.g., °C or °F)

For more details refer to this publication.

EHS Compliance

If the water from your blow-down needs to be discharged, any discharge your system creates will need to meet all regulatory requirements. In certain areas where water is scarce, there could be large sewer connection fees, and demineralization systems can be a cost-effective solution here, as they can help minimise the cost to connect to water and sewer lines. Also, the discharge of your cooling tower bleed must meet local municipal discharge regulations if your effluent is being returned to the environment or a publicly owned treatment works. Any human contact with a cooling system needs to be risk assessed for Legionella too. Look at our Legionella Management presentation.

Safety

Follow all local safety regulations and always remember that cooling towers are bacterial incubators so it is a good idea that you are Legionella aware. Download our presentation on Legionella Management here. Also beware of chemical over dosing this is a real risk.

Toward Net Zero

Solving Climate Change is one of the global challenges of the 21st Century. More efficient cooling is one of the ways to work toward that end. Waste heat from data centres for example can be used for District Heating in cold climate cities. District Cooling is also an efficient way to cool large cities in hot countries like the Emirates and Saudi Arabia.

Professional Standards:

Professional Standards/Guidelines in use for cooling water systems include VGB, VDI, BSRIA, CIBSE, HSG 274 and L8 ACOP.

Contact us for more information. We are specialists in Cooling Tower chemistry.

Biography of the Author:

Rami Elias Kremesti is a chartered water and wastewater treatment specialist with a background in chemistry. He has worked on a myriad of water treatment and power station projects internationally. He is a British Citizen based out of High Wycombe, UK. He has published three books on philosophical topics which he loves to ponder in his spare time.

Rami Elias Kremesti Portrait

If you found this page useful, please leave us a positive review on Google.