TRANSFORMING BASE SUBSTANCES INTO GOLD

Ozone In Water Treatment

Introduction and A Little Bit of History

Ozone is a powerful oxidant used in water treatment. It was discovered by German chemist Christian Friedrich Schönbein in 1840, who also named it, and the first known application of ozone in water treatment was pioneered by Marius Paul Otto in the late 19th century.

Marius Paul Otto, a French scientist in the late 19th century, made significant strides in understanding and applying ozone, particularly in water treatment, demonstrating its effectiveness as a disinfectant. In 1886, he established the Compagnie des Eaux d’Ozone in France, an organization company dedicated to developing ozone technology and driving early commercial application.

Ozone In Pre-treatment and Post-treatment of Water and Waste Water

Ozone is highly reactive gas with a pungent smell composed of three atoms of oxygen . It has a complex impact on water/wastewater parameters – it

- reduces colour,

- improves taste and odour,

- kills bacteria and viruses,

- oxidises ferrous iron, manganese,

- Oxidises cyanides, phenol, benzene, chlorophenol, atrazine, nitrobenzene and other organic pollutants.

- It degrades PFAS/PFOS

Ozone application increases the biodegradability of wastewater and hence COD:BOD ratio decreases.

There are some very important applications that use Ozone.

Ozone Treatment of Return Activated Sludge (RAS) in Sewage Treatment

MLR (Mixed Liquor Recirc) is an internal recirculation line from aerobic to anoxic tanks and RAS is from the secondary sedimentation to incoming flow from primary treatment. The high water content, compressible and colloidal nature of the sludge are common characteristics found in WWTP. Filamentous bacteria are a normal part of the activated sludge microflora while excessive long filaments lead to sludge bulking (floating sludge) and prevent sedimentation.

Dosing ozone in the RAS promotes the growth of floc forming bacteria and inhibits the activity of filamentous bacteria which enhances sludge bulking and inhibits sedimentation. Low concentrations of ozone can be used as an approach to promoting floc formation and inhibit the activity of filamentous bacteria and sludge bulking.

Figure 1. Floating Bulked Sludge

Ozone Disinfection in Post-treatment

Disinfection of water using ozone is advantageous compared to more traditional methods, such as chlorine, bromine or UV disinfection. Ozone effectively breaks down the lipid layers in the cell membrane. It is more effective at deactivating viruses and bacteria than any other disinfection treatment, while at the same time requiring very little contact time.

Advantages and Disadvantages

Disinfection of water using ozone has its advantages and disadvantages compared to more traditional methods, such as chlorine or UV disinfection.

Firstly, ozone is more effective at deactivating viruses and bacteria than any other disinfection treatment, while at the same time requiring very little contact time, thus reducing the overall treatment residence time/reactor size while simultaneously leaving no chemical residues.

Due to the high oxidation potential, ozone will effectively degrade microbes and viruses, causing cell membrane rupture and decomposition of essential biomolecular components. It works only in colder waters with a T up to 30 C. At higher temperatures, it flashes too quickly.

There are essentially no harmful residuals from ozone use, as ozone undergoes a natural decomposition in water and reverts back to Oxygen. Ozone treatment also prevents re-growth of micro-organisms, provided that the other processes in the disinfection process have been successful in reducing particulates in the wastewater stream.

Ozone is also produced on site and does not require shipping or handling of chemicals, thus removing complications like safety and environmental issues associated with chemical handling. The fact that Ozone reverts back to Oxygen in water makes the water corrosive to Carbon steel which is one of its disadvantages also. Also any O3 leaks are dangerous to personnel. It is also an expensive technology to implement.

The disadvantage of Ozone is that it is still expensive to produce, it requires special materials to handle it, and it leaves no residual disinfectant levels after distribution. Indoor production can be dangerous due to system leaks.

Disinfection Efficiency

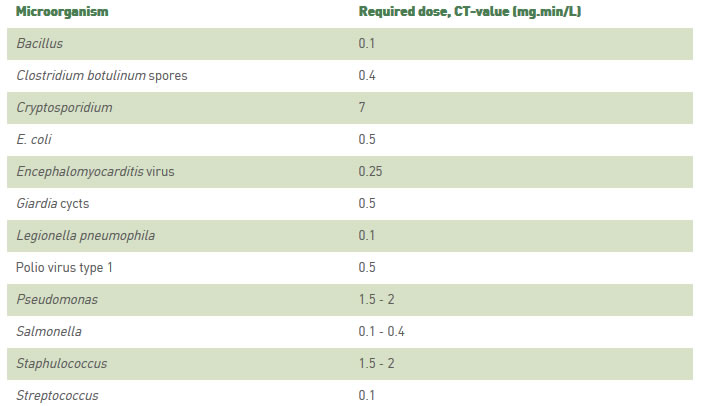

As already stated above ozonation will enable efficient disinfection. The disinfection efficiency is commonly measured using the CT-value (concentration multiplied by time). In the image below a comparison between ozone and chlorination alternatives is shown.

Ozonation provides protection against essentially all toxic and harmful unwanted microbes. In the table below the CT-values for a range of germs are listed.

Figure 2. Concentration x Contact Time values for Ozone for various microorganisms

Disinfection Pre-requisites For Drinking Water Production

Drinking water disinfection comes after other water purification steps. Proper disinfection can only take place when the water is sufficiently pretreated i.e. clear. In many cases the disinfection process is one of the final steps in a water treatment system. In drinking water treatment the disinfection step is preceded by screening, sedimentation, flocculation, and sand filtration. At this point the water will be suitable for final disinfection.

Dissolved and suspended particles should be removed from water since the particles may contain substrate (food) for pathogenic growth. Moreover, microorganisms are harder to remove from water when they are adsorbed to particles. The concentrations of undissolved particles in water should be reduced below 1 mg/l prior to disinfection. Other chemical compounds from human or natural sources also influence the performance of the disinfection treatment. The substances may react with disinfectants to form disinfection byproducts and increase the Ozone demand to levels that are not economical.

The EC Drinking Water Directive included a limit of 0.1 µg/L (ppb) for individual pesticides, a standard far more stringent than health-based minimum levels set by such bodies as the World Health Organizations and the US EPA. With traditional treatment processes such as chemical coagulation, flocculation, filtration and slow sand filtration unable to meet the stricter pesticide standard, an additional method of treatment was required. Consequently, ozone and granular activated carbon (GAC) have been installed at all the major drinking water treatment works in London and Oxford treating river Thames water.

Also note that hardness levels and pH levels play an important role in the effectiveness of Ozone in water treatment. At high pH, ozone loses its efficacy.

Some Other Applications of Ozone in Water Treatment:

CIP (Clean in Place) of bio-reactors in the Pharmaceutical industry

TOC reduction in demin water production

Bleaching

Bottle Rinsing/Bottled water

Vegetable Washing

Swimming Pools: Posh Swimming Pools use Ozone because it does not smell or hurt the eyes.

Real posh swimming pools use no chemicals at all…. Their water is Biostable and uses natural UV light for disinfection.

Ozone in Agriculture – Fighting Root Fungus

Ozone Use in Advanced Oxidation Processes (AOP)

Advanced oxidation processes (AOPs) are defined as the oxidation processes which generate very powerful, non-selective hydroxyl radicals that are utilized in water treatment. AOPs are comparatively new and intensively developing technique. Ozone based AOPs are the processes where ozonation is applied simultaneously with UV radiation, hydrogen peroxide, activated carbon, catalysts, ultrasound – methods that rely primarily on oxidation with hydroxyl radicals. Such approaches aims to improve the efficacy of ozonation:

a. to enhance the oxidation rate of contaminants (and consequently ascertain higher COD and BOD reduction);

b. to lower the ozone consumption;

c. to improve the biodegradability of the by-products, etc.

AOPs have high potential to degrade organic water contaminants that are not attacked by chlorine and ozone. Ozone-based AOPs

have developed from the laboratory to full-scale applications and are successfully used for both the wastewater and drinking water treatment. None of the individual AOPs is universally applicable or highly effective for every kind of the wastewater. They are not to be employed whenever cheaper technologies are effective. However, they are indispensable for special water treatment needs.

There are a few highly specialized companies that do AOP:

Arvia – UK

Lummus – Electro AOP

Ozone in Cooling Towers

Cooling towers are a relatively new sector for ozone treatment. As such, the benefits of the technology are still being discovered by the users in this sector. The main advantages of ozone water treatment over the traditional chemical water treatment are in the water and energy savings that can be made. The reduction, and possible elimination, of chemical use also creates cost benefits for the user.

The first problem facing water cooling towers is the build up of biological growth and minerals, otherwise known as scale. These problems inhibit the cooling towers’ heat transfer efficiency. The way this problem has been solved in the past has been through the use of chemical agents such as chlorine and chelating/corrosion inhibitor agents. While this serves as an adequate solution to the original problem, the chemicals lead to other problems. Because of the evaporation of water in the tower, the remaining water reaches a high level of chemical and contaminant concentration. To regulate this, water is bled out of the system, and replaced by fresh “make up” water. It is the bleed water that can be problematic to dispose of, with extra sewage cost being incurred.

Ozone treatment solves the original problem with a vastly reduced number of secondary costs and considerations. As well as being a powerful biocide, ozone has been proven to have a positive de-scaling effect. It also greatly reduces the level of bleed off water, as well as the per unit cost of disposing it due to the environmentally friendly nature of ozone. Added to this are the savings due to reduced storage costs and handling of chemicals as ozone is produced on site. This fact significantly simplifies regulatory compliance.

Ozone: Mechanism of Action

Ozone effectively inactivates and kills microorganisms by oxidizing their organic constituents and rupturing the cell walls. It is a biocidal process to which microbes cannot develop immunity. For example a 0.4 mg/L concentration results in 100 % kill in 2 – 3 minutes for the biofilm producer Pseudomonas fluorescens. A 0.1 mg/L concentration will remove about 80 % of the biofilm in 3 hours. Ozonation technology also has beneficial scaling treatment effects. By removing biofilm to which scale is adhered scaling effects can be significantly reduced when biofilm is present.

Ozone also attacks organic molecules, thus oxidizing them and breaking them down into smaller molecules. #

Important Design parameters to consider when using ozone treatment

The following aspects should all be considered when designing, installing, and utilizing ozone in cooling towers:

- Preparation of inlet air to ozone generator. To maximize life time and capacity of the ozone generator a dry, concentrated air feed should be supplied.

- Adequate dosing and capacity of ozone generator should be factored in based on water chemistry

- Efficient ozone generator cooling. This is also critical to achieve long life times and capacity of the generator.

- Harder to use where high COD-levels are introduced to the water from water makeup or local air conditions. This consumes the ozone residual. For example, this is the reason why ozone treatment is more difficult in some chemical- and petrochemical plants where organic material is introduced to the system from the air.

- A makeup water quality of above 150 ppm calcium hardness may require a side softener filter. Calcium (CaCO3) hardness of above 500 ppm or sulfates above 100 ppm should not be considered for ozone treatment. High hardness can come with other cations that will effect the decomposition of Ozone.

- Water temperature. The cooling water temperature should not exceed 45 C for efficient ozone treatment. This is mainly because of the low solubility of ozone at higher temperatures.

- Long piping systems. Because of the short half life time of about 10 – 15 multiple injection points may be required in cooling towers larger than about 400 m3.

- Use ozone compatible materials for gaskets and valve internals and monitor corrosion (e.g. using corrosion coupons).

- Choice of Materials (SS, UPVC are OK for piping and fittings, Viton is needed for seals that are exposed to high levels of Ozone > 0.5 ppm)

- In wastewater treatment, pH significantly influences ozone’s activity by affecting its decomposition rate and the type of reactions it undergoes. Higher pH generally leads to faster ozone decomposition and increased formation of hydroxyl radicals (·OH), which are powerful oxidants, while lower pH favours direct ozone reactions.

Ozone Decomposition In Water – Chemical Factors

Hydroxide (OH-) ions, perhydroxyl (HO–) ions, and certain transition metal ions like silver (Ag+) and copper (Cu²+) promote the decomposition of ozone in water, while carbonate (CO3)-2 and bicarbonate (HCO3-) ions act as scavengers, also contributing to ozone decomposition, especially carbonate ions. The presence of these ions, along with increased pH, higher temperatures, and organic compounds, accelerates the natural breakdown/consumption of ozone into oxygen.

Iron-containing compounds, often in conjunction with other metals, also promote the decomposition of ozone in water, with compounds like ferric hydroxide demonstrating significant catalytic activity.

Measuring Ozone In Water

We all know that the Ozone layer protects us from UV’s damaging effects. This means that Ozone absorbes UV ! This property is used to quantify Ozone in water which can be measure using a UV-Vis spectrophtometer. Ozone also affects the ORP so a before and after change in ORP can be detected instantaneously when Ozone is dosed. Finally, as Ozone is an oxidant, it will oxidise Sodium Bi Sulphite to Sulphate and hence can be quantified by measuring Sulphates in wet chemistry applications.

Ozone Humour

“A Sniff of Ozone A Day, Keeps The Doctor Away” – by Rami Elias Kremesti. I coined this expression when I used to work for SOCOTEC, they make small Ozone systems.

But on a serious note, there is medical literature there which points to the therapeutic uses of Ozone in treating diseases like inflammation.

Practical Ozone Scaling Index (POSI)

To monitor and control scaling in cooling towers when using ozone treatment, the POSI index was developed by Pryor and Fischer in 1993. It gives the maximum operation conductivity for the cooling tower to avoid scaling and it takes the reduced amount of dissolved calcium (by using ozonation) into account. The index is explained in the formula below:

Ozone allegedly allows Cooling Towers to achieve higher Cycles of Concentration.

Here is an interesting study that touches on POSI: https://catalog.lib.kyushu-u.ac.jp/opac_download_md/4742140/904-909.pdf

Reliable Suppliers of Ozone Generating equipment for Water Treatment Applications:

De Nora, Italy

WEDECO/Xylem

Ozone Tech, Sweden part of the Mellifiq group.

Prominent Dosiertechnik

Swiss Ozonia eventually became part of Veolia

SOCOTEC UK for Small Ozone Systems

Ozcon – Originally from Turkey

Lenntech – Netherland

Anseros – Germany

Ozone In Air Treatment

Ozone, a powerful oxidizing agent, is widely used to improve air quality by purifying it from harmful gases, odors, and bacteria. Its ability to disinfect and remove pollutants makes it an ideal solution for a variety of air treatment applications. Some indoor air purifiers used Ozone. Some suppliers use Ozone to treat odour from restaurant cooking aspirators in areas that are sensitive/densely populated and are highly regulated.

References:

Ozone Tech Website https://www.ozonetech.com/

Developed by Rami E. Kremesti M.Sc. CSci, CEnv, CWEM

Contact us for more information on Ozone in Water Treatment.

Biography of the Author:

Rami Elias Kremesti is a chartered water and wastewater treatment specialist with a background in chemistry. He has worked on a myriad of water treatment and power station projects internationally. He is a British Citizen based out of High Wycombe, UK. He has published three books on philosophical topics which he loves to ponder in his spare time.

If you found this page useful, please leave us a positive review on Google.

Rami Elias Kremesti Portrait